Center Line Wafer Butterfly Valves

Likaroloana

▪ Double eccentric, Triple eccentric type bakeng sa khetho.

▪ Rabara e lutseng, Metal e lutseng mofuta oa khetho.

▪ Sebopeho sa mahala sa phini pakeng tsa ho hokahanya ha valve disc le stem ho hlōla sebaka se ka khonehang sa ho lutla ka hare.

▪ Torque e nyane e bulehang, e tenyetseha ebile e bonolo ho e sebelisa, e baballa mosebetsi ebile e baballa matla.

▪ Sebopeho se ikhethileng, boima bo bobebe, bo bonolo ho bula le ho koala.

▪ E ka kenngoa sebakeng leha e le sefe 'me e bonolo bakeng sa tlhokomelo.

▪ Ho hana mocheso o phahameng, mocheso o tlase le ho bola.

▪ E sebelisoa haholo mefuteng ea maemo a mosebetsi le mekhoa ea ho sebetsa.

▪ Mochine o ikhethileng oa ho bonts'a serurubele se tšekaletseng se kentsoeng ka tlas'a lefatše.

▪ Khatello ea teko:

Khatello ea Tlhahlobo ea Shell 1.5 x PN

Khatello ea Teko ea Tiiso 1.1 x PN

Litlhaloso tsa Lintho

| Karolo | Lintho tse bonahalang |

| Mmele | Alloy steel, Ductile iron, Stainless steel, Chrome molybdenum steel, Alloy steel, Duplex stainless steel, Grey cast iron, |

| Diski | Alloy steel, Ductile iron, Stainless steel, Chrome molybdenum steel, Alloy steel, Duplex stainless steel, Grey cast iron, |

| Letsoako | 2Cr13, 1Cr13 tšepe e sa hloekang, Cr-Mo.tšepe, tšepe e sa hloekang ea Duplex |

| Setulo | Tšepe e sa hloekang, Cr-Mo.tšepe, tšepe e sa hloekang ea Duplex |

| Lesale la ho Tiisa | Boto ea asbestos ea tšepe e sa hloekang le mocheso o phahameng e kopantsoe ka mekhahlelo e mengata |

| Ho paka | graphite e feto-fetohang, asbestos ea Graphite, PTFE |

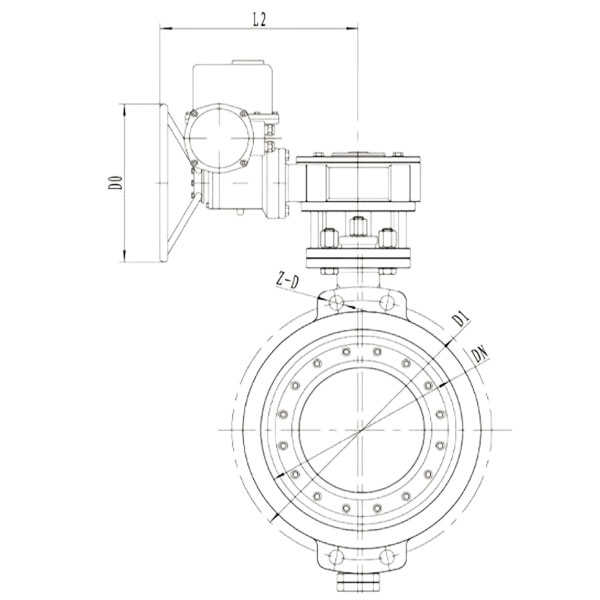

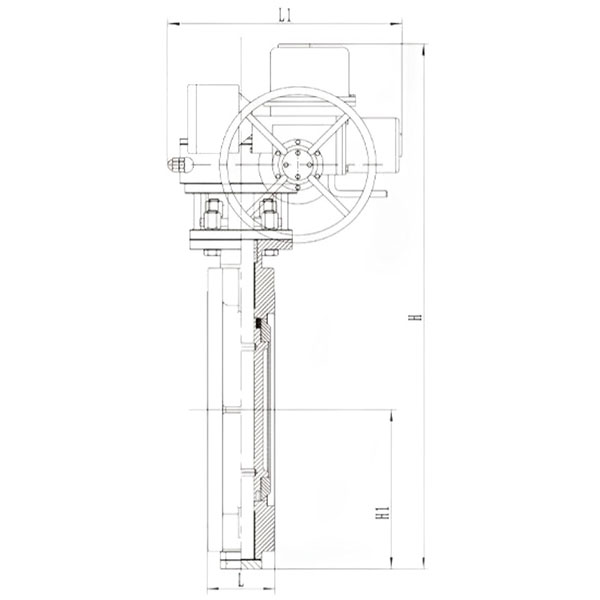

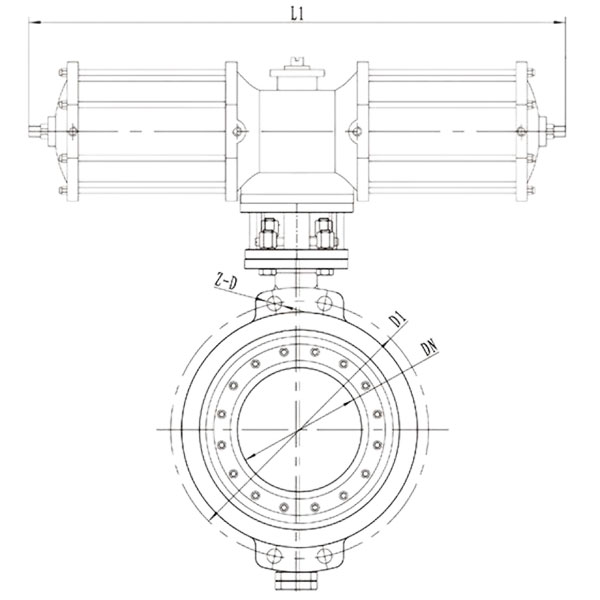

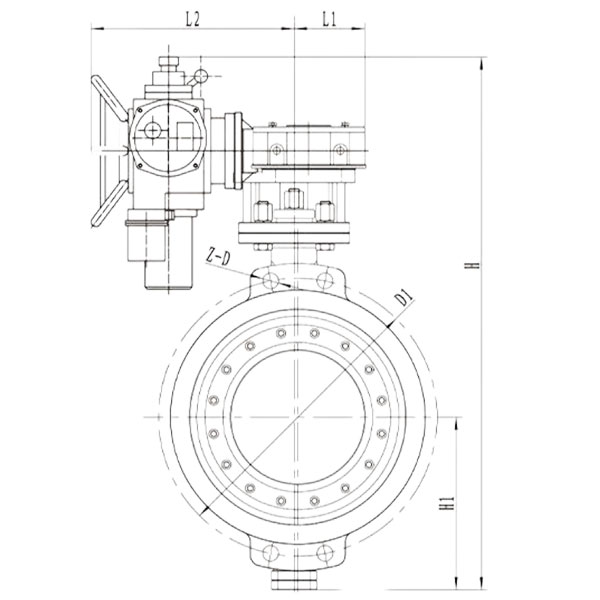

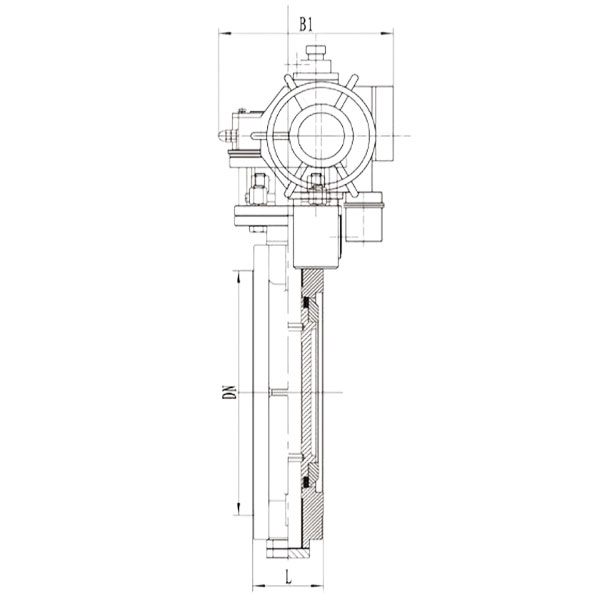

Sekema

Re fana ka

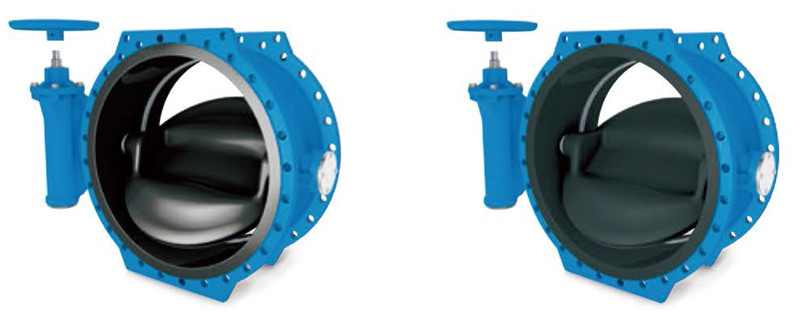

▪ Li-Valves tsa Lirurubele tse lutseng tse peli tsa Eccentric Ruber

▪ Li-Valves tsa Lirurubele tse lutseng habeli tsa Eccentric Metal

▪ Li-Valves tsa Triple Eccentric Metal Seated Wafer Butterfly

▪ Mefuta e Meng Li-valve tsa Serurubele sa Wafer

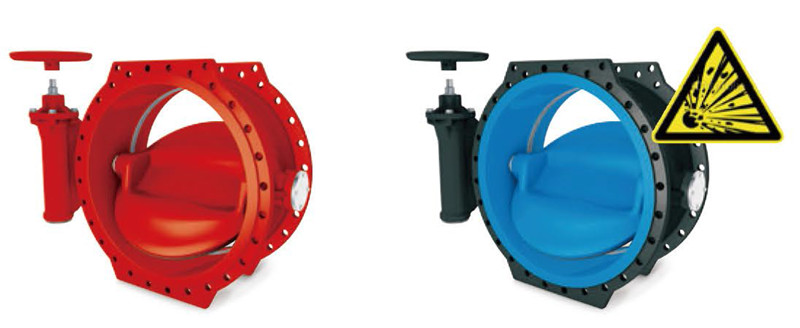

Tšireletso ea Bokaholimo - E Loketse Maemo a fapaneng a ho sebetsa

▪ Karolo e ka holimo ea valve e phekoloa ka mokhoa oa ho qhomisa lehlabathe, ebe ka ho fafatsa ka polasetiki kapa mokhoa oa ho penta ho latela boholo ba valve.

▪ Theknoloji e tsoetseng pele ea ho fafatsa li-valve e thusa valve hore e sireletsehe hantle maemong afe kapa afe a ho sebetsa.

Ho roala

▪ Seaparo se Tloaelehileng sa Epoxy

Ho roala ha epoxy resin ke thepa e tloaelehileng ea ho thibela ho bola.Ho na le melao e thata bakeng sa botenya le mocheso ts'ebetsong ea phekolo.Mocheso o tlameha ho fihla ho 210 ℃, 'me botenya ha bo ka tlaase ho 250 microns kapa esita le 500 microns.Ho roala ha ho na kotsi 'meleng oa motho' me ho bolokehile ka ho feletseng bakeng sa metsi a nooang.

▪ Tšireletso e Khethehileng bakeng sa Tšireletso ea Corrosion

Ho roala ho khethehileng ho fana ka tšireletso e ka tšeptjoang bakeng sa valve, haholo-holo bakeng sa maemo a mang a thata a ho sebetsa, a kang acid kapa alkali media, metsi a nang le sediment, tsamaiso ea pholileng, tsamaiso ea matla a metsi, metsi a leoatle, metsi a letsoai le metsi a litšila a indasteri.

EPC (Ceramic le Epoxy Double Component Coating)

Seaparo sa Rubber se thata kapa se bonolo

Penta ea Polyurethane ka hare le ka ntle

Bokantle ba Conductive Coating ho Qoba Mollo

Kopo

▪ E kentsoe ka har'a phepelo ea metsi le likhoerekhoere, likhoerekhoere, lijo, phepelo ea ho futhumatsa, khase, likepe le likepe, motlakase oa metsi, metallurgy, tsamaiso ea matla, masela a bobebe le liindasteri tse ling, haholo-holo tse loketseng bakeng sa ho koala ka tsela e 'meli le linakong tseo ho tsona setopo sa valve se leng teng. ho mafome ha bonolo.Belofo ke valve e tloaelehileng ea serurubele e ratoang bakeng sa liphaephe, e nang le sebopeho se bonolo, coefficient e nyenyane ea ho hanyetsa phallo, litšoaneleho tsa ho phalla ha mela le ha ho na li-sundries.E ka sebelisoa eseng feela ho khaola seaplane, empa hape le ho lokisa phallo ea seaplane.